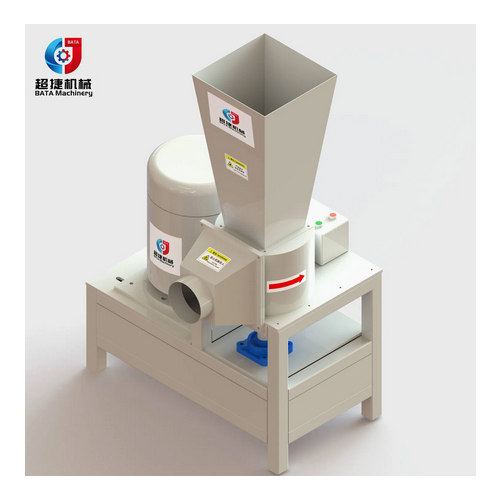

High-Efficiency Foam Shredder for Fast Material Processing Solutions

High-Efficiency Foam Shredder for Fast Material Processing Solutions Specification

- Warranty

- 2-5 Years

- Color

- White

- Application

- Industrial

- Voltage

- 200 - 250 Volt (v)

- Control System

- Manual

- Processing Type

- Standard

- Automatic Grade

- Semi Automatic

- Size

- Standard

High-Efficiency Foam Shredder for Fast Material Processing Solutions Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 7 - 10 Days

- Main Domestic Market

- All India

About High-Efficiency Foam Shredder for Fast Material Processing Solutions

The High-Efficiency Foam Shredder is designed for fast material processing in industrial applications. Engineered for reliability and ease of use, this semi-automatic shredder operates on a voltage range of 200-250 volts, ensuring compatibility with standard power systems. Its manual control system offers precise handling, making it suitable for diverse material shredding tasks. Built to last, the shredder comes with a generous warranty period of 2 to 5 years, ensuring peace of mind for business operations. With a standard processing type, this foam shredder offers the perfect balance between durability and efficiency, making it an ideal solution for industries requiring high-performance equipment. Constructed for manufacturers, suppliers, and exporters, this shredder is the go-to choice for effective foam material processing.

FAQs of High-Efficiency Foam Shredder for Fast Material Processing Solutions:

Q: What type of control system does the High-Efficiency Foam Shredder feature?

A: It features a manual control system, enabling users to manage operations precisely.Q: Is the shredder fully automatic?

A: No, the shredder is semi-automatic, combining automation and manual operation for optimal performance.Q: What is the voltage requirement for this shredder?

A: The shredder operates on a voltage range of 200-250 volts, compatible with standard industrial power systems.Q: What industries can benefit from this foam shredder?

A: It is ideal for industrial applications where efficient foam material processing is needed.Q: How long is the warranty period for this shredder?

A: The shredder comes with a warranty period of 2-5 years.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Foam Shredding Machine Category

Waste Foam cutting machine with high cfficient

Price 124.0 USD ($) / Set

Minimum Order Quantity : 14 Sets

Voltage : 220440 Volt (v)

Automatic Grade : Automatic

Size : Standard

Warranty : 1 Year

Foam shredding machine

Price 10900.0 USD ($) / Set

Minimum Order Quantity : 1 Set

Voltage : 220415 Volt (v)

Automatic Grade : Yes

Size : Standard

Warranty : 1 year

Versatile Foam Shredder and Grinder for Industrial Use

Price 16154 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 200 250 Volt (v)

Automatic Grade : Semi Automatic

Size : Standard

Warranty : 25 Years

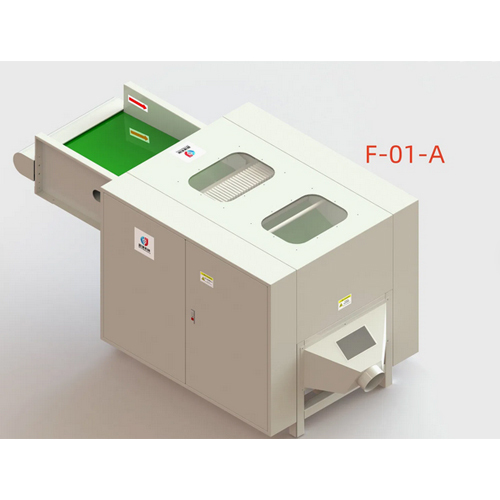

Latex Memory Foam Cutter Viscoelastic Foam Mattress Recycling Machine

Price 16154 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 200 250 Volt (v)

Automatic Grade : Semi Automatic

Size : Standard

Warranty : 25 Years

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese